Double-Acting Actuator (TL-G)

Linear actuator with opposing thermal liquid and gas chambers

Libraries:

Simscape /

Fluids /

Thermal Liquid /

Actuators

Description

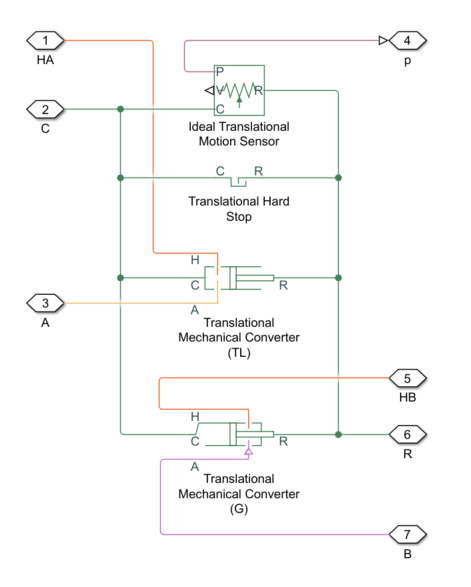

The Double-Acting Actuator (TL-G) block models a linear actuator with opposing chambers of thermal liquid and gas. The chambers can be individually pressurized to power the actuator in both extension and retraction strokes. A piston between the chambers converts the pressure difference across them into actuation force.

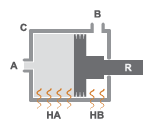

The figure maps the conserving ports of the block to the actuator parts. Ports A and B are the inlets of the thermal liquid and gas chambers. Ports R and C are the translating piston and case. The chambers can exchange heat with the environment and are fitted for this purpose with ports HA and HB. The piston is perfectly insulating. The thermal liquid and gas chambers do not exchange heat with each other.

The sign of the piston displacement relative to the case depends on the mechanical orientation of the actuator. Use the Mechanical orientation parameter to specify this setting. If the mechanical orientation is positive, the piston displacement is positive when the pressure is highest in the thermal liquid chamber (port A). If the mechanical orientation is negative, the piston displacement (under the same pressure conditions) is negative.

Use port P to output the instantaneous piston position. The measurement is absolute (relative to zero). Hard stops limit the motion of the piston to the length of the case. The stops are modeled as spring-dampers, with spring and damping coefficients to capture material compliance. One is located at the bottom of the piston stroke and the other at the top:

If the Mechanical orientation setting is

Positive, the bottom stop is at zero, and the top stop is at a distance equal to the piston stroke.If the Mechanical orientation setting is

Negative, the top stop is at zero, and the bottom stop is at a distance equal to the piston stroke.

The block is a composite component built from Simscape™ Foundation blocks. For more information on how the Double-Acting Actuator (TL-G) block works, see the reference pages of the constituent blocks: