Pipe (TL)

Closed conduit that transports fluid between thermal liquid components

Libraries:

Simscape /

Fluids /

Thermal Liquid /

Pipes & Fittings

Description

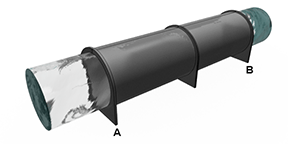

The Pipe (TL) block represents thermal liquid flow through a pipe. The block finds the temperature across the pipe from the differential between ports, pipe elevation, and any additional heat transfer at port H.

The pipe can have a constant or varying elevation between ports A

and B. For a constant elevation differential, use the

Elevation gain from port A to port B parameter. You can specify

a variable elevation by setting Elevation gain specification to

Variable. This exposes physical signal port

EL.

You can choose to include the effects of fluid dynamic compressibility, inertia, and wall flexibility. When the block includes these phenomena, it calculates the flow properties for each number of pipe segments that you specify.

Pipe Geometry

Use the Cross-sectional geometry parameter to specify the shape of the pipe.

The nominal hydraulic diameter, DN, and the pipe diameter, dcircle, are both equal to the is the value of the Pipe diameter parameter. The pipe cross-sectional area is

The nominal hydraulic diameter is the difference between the Pipe outer diameter and Pipe inner diameter parameters DN = douter – dinner. The pipe cross-sectional area is

The nominal hydraulic diameter is

where:

h is the is the value of the Pipe height parameter.

w is the is the value of the Pipe width parameter.

The pipe cross-sectional area is

The nominal hydraulic diameter is

where:

amaj is the is the value of the Pipe major axis parameter.

bmin is the is the value of the Pipe minor axis parameter.

The pipe cross-sectional area is

The nominal hydraulic diameter is

where:

lside is the is the value of the Pipe side length parameter.

θ is the is the value of the Pipe vertex angle parameter.

The pipe cross-sectional area is

When the Cross-sectional geometry parameter is

Custom, you can specify the pipe cross-sectional

area with the Cross-sectional area parameter. The nominal

hydraulic diameter is the value of the Hydraulic diameter

parameter.

Pipe Flexibility

You can model flexible walls for all cross-sectional geometries. When you set

Pipe wall specification to

Flexible, the block assumes uniform expansion along

all directions and preserves the defined cross-sectional shape. This setting may not

result in physical results for noncircular cross-sectional areas undergoing high

pressure relative to atmospheric pressure. When you model flexible walls, you can

use the Volumetric expansion specification parameter to specify

the volumetric expansion of the pipe cross-sectional area.

When the Volumetric expansion specification parameter is

Cross-sectional area vs. pressure, the change in

volume is

where:

L is the Pipe length parameter.

SN is the nominal pipe cross-sectional area defined for each shape.

S is the current pipe cross-sectional area.

p is the internal pipe pressure.

patm is the atmospheric pressure.

Kps is the Static gauge pressure to cross-sectional area gain parameter.

To calculate Kps assuming uniform elastic deformation of a thin-walled, open-ended cylindrical pipe, use

where t is the pipe wall thickness and E is Young's modulus.

τ is the Volumetric expansion time constant.

When the Volumetric expansion specification parameter is

Cross-sectional area vs. pressure - Tabulated, the

block uses the same equation for as the Cross-sectional area vs.

pressure setting. The block calculates A with

the table lookup function

where pps is the Static gauge pressure vector parameter and Aps is the Cross sectional area gain vector parameter.

When the Volumetric expansion specification parameter is

Hydraulic diameter vs. pressure, the change in volume is

where:

DN is the nominal hydraulic diameter defined for each shape.

D is the current pipe hydraulic diameter.

Kpd is the Static gauge pressure to hydraulic diameter gain parameter. To calculate Kps assuming uniform elastic deformation of a thin-walled, open-ended cylindrical pipe, use

When the Volumetric expansion specification parameter is

Based on material properties, the block uses the same

equation for as the Hydraulic diameter vs. pressure

setting but calculates Dstatic depending

on the value of the Material behavior parameter

This parameterization assumes a cylindrical thin-walled pressure vessel where

When the Material behavior parameter is Linear

elastic,

where:

E is the value of the Young's modulus parameter.

v is the value of the Poisson's ratio parameter.

, where t is the value of the Pipe wall thickness parameter.

When the Material behavior parameter is

Multilinear elastic, the block calculates the von

Mises stress, σv, which simplifies to , to determine the equivalent strain. The hoop strain is

where:

The block calculates the Young's Modulus, E, from the first elements of the Stress vector and Strain vector parameters.

, where σtotal and εtotal are the equivalent total stress and the equivalent total strain, respectively. The block calculates the equivalent total strain from the von Mises stress and the stress-strain curve.

where σi,j are the elements of the Cauchy stress tensor.

If you do not model flexible walls, SN = S and DN = D.

If you select Pipe thermal expansion, the block models the thermal expansion of the pipe wall using these assumptions:

The pipe material is isotropic.

The Biot number of the pipe is less than 0.1 and the pipe can be modeled with lumped thermal capacitance.

The temperature change and pipe deformations are small enough that a first order approximation for area expansion is accurate.

When the Material behavior parameter is

Cross-sectional area vs. pressure,

Cross-sectional area vs. pressure - Tabulated, or

Hydraulic diameter vs. pressure and you select

Pipe thermal expansion, the block adds a thermal

expansion term when calculating area or diameter.

When Material behavior is Cross-sectional

area vs. pressure,

where:

ɑ is the value of the Coefficient of thermal expansion parameter.

TI is the fluid temperature at the internal node of the block.

Tref is the value of the Thermal expansion reference temperature parameter.

When Material behavior is Cross-sectional

area vs. pressure - Tabulated,

When Material behavior is Hydraulic diameter

vs. pressure ,

When the Material behavior parameter is

Multilinear elastic and you select Pipe

thermal expansion, the block calculates

Dstatic as

where

Heat Transfer at the Pipe Wall

You can include heat transfer to and from the pipe walls in multiple ways. There

are two analytical models: the Gnielinski correlation,

which models the Nusselt number as a function of the Reynolds and Prandtl numbers

with predefined coefficients, and the Dittus-Boelter correlation -

Nusselt = a*Re^b*Pr^c, which models the Nusselt number as a

function of the Reynolds and Prandtl numbers with user-defined coefficients.

The Nominal temperature differential vs. nominal mass flow

rate, Tabulated data - Colburn factor vs. Reynolds

number, and Tabulated data - Nusselt number vs.

Reynolds number & Prandtl number are lookup table

parameterizations based on user-supplied data.

Heat transfer between the fluid and pipe wall occurs through convection, QConv and conduction, QCond, where the net heat flow rate, QH is QH=QConv+QCond.

Heat transfer due to conduction is:

where:

D is the nominal hydraulic diameter, DN, if the pipe walls are rigid, and is the pipe steady-state diameter, DS, if the pipe walls are flexible.

kI is the thermal conductivity of the thermal liquid, defined internally for each pipe segment.

SH is the surface area of the pipe wall.

TH is the pipe wall temperature.

TI is the fluid temperature at the internal node of the block.

Heat transfer due to convection is:

where:

cp, Avg is the average fluid specific heat which the block calculates using a lookup table.

Avg is the average mass flow rate through the pipe.

TIn is the fluid inlet port temperature.

h is the pipe heat transfer coefficient.

The heat transfer coefficient h is:

except when parameterizing by Nominal temperature

differential vs. nominal mass flow rate, where

kAvg is the average thermal

conductivity of the thermal liquid over the entire pipe and Nu is

the average Nusselt number in the pipe.

When Heat transfer parameterization is set to

Gnielinski correlation and the flow is turbulent,

the average Nusselt number is calculated as:

where:

f is the average Darcy friction factor, according to the Haaland correlation:

where εR is the pipe Internal surface absolute roughness.

Re is the Reynolds number.

Pr is the Prandtl number.

When the flow is laminar, the data from [1] determines how the Nusselt number depends on the Cross-sectional geometry parameter:

When Cross-sectional geometry is

Circular, the Nusselt number is 3.66.When Cross-sectional geometry is

Annular, the block calculates the Nusselt number from tabulated data using a lookup table with linear interpolation and nearest extrapolation.Nusselt number 1/20 17.46 1/10 11.56 1/4 7.37 1/2 5.74 1 4.86 The block adjusts the calculated Nusselt number with a correction factor

When Cross-sectional geometry is

Rectangular, the block calculates the Nusselt number from tabulated data using a lookup table with linear interpolation and nearest extrapolation.Nusselt number 0 7.54 1/8 5.60 1/6 5.14 1/4 4.44 1/3 3.96 1/2 3.39 1 2.98 When Cross-sectional geometry is

Elliptical, the block calculates the Nusselt number from tabulated data using a lookup table with linear interpolation and nearest extrapolation.Nusselt number 1/16 3.65 1/8 3.72 1/4 3.79 1/2 3.74 1 3.66 When Cross-sectional geometry is

Isosceles triangular, the block calculates the Nusselt number from tabulated data using a lookup table with linear interpolation and nearest extrapolation.θ Nusselt number 10π/180 1.61 30π/180 2.26 60π/180 2.47 90π/180 2.34 120π/180 2.00 When Cross-sectional geometry is

Custom, the Nusselt number is the value of the Nusselt number for laminar flow heat transfer parameter.

When Heat transfer parameterization is set to

Dittus-Boelter correlation and the flow is

turbulent, the average Nusselt number is calculated as:

where:

a is the value of the Coefficient a parameter.

b is the value of the Exponent b parameter.

c is the value of the Exponent c parameter.

The block default Dittus-Boelter correlation is:

When the flow is laminar, the Nusselt number depends on the Cross-sectional geometry parameter.

When the Heat transfer parameterization parameter is set

to Tabulated data - Colburn factor vs. Reynolds

number, the average Nusselt number is calculated as:

where JM is the Colburn-Chilton factor.

When the Heat transfer parameterization parameter is set

to Tabulated data - Nusselt number vs. Reynolds number &

Prandtl number, the Nusselt number is interpolated from the

three-dimensional array of average Nusselt number as a function of both average

Reynolds number and average Prandtl number:

When the Heat transfer parameterization parameter is set

to Nominal temperature difference vs. nominal mass flow

rate and the flow is turbulent, the heat transfer coefficient

is calculated as:

where:

N is the value of the Nominal mass flow rate parameter.

Avg is the average mass flow rate:

hN is the nominal heat transfer coefficient, which is calculated as:

where:

SH,N is the nominal wall surface area.

TH,N is the value of the Nominal wall temperature parameter.

TIn,N is the value of the Nominal inflow temperature parameter.

TOut,N is the value of the Nominal outflow temperature parameter.

This relationship is based on the assumption that the Nusselt number is proportional to the Reynolds number:

If the pipe walls are rigid, the expression for the heat transfer coefficient becomes:

Pressure Loss Due to Friction

The analytical Haaland correlation models losses due to wall friction either by aggregate equivalent length, which accounts for resistances due to nonuniformities as an added straight-pipe length that results in equivalent losses, or by local loss coefficient, which directly applies a loss coefficient for pipe nonuniformities.

When the Local resistances specification parameter is set

to Aggregate equivalent length and the flow in the

pipe is lower than the Laminar flow upper Reynolds number

limit, the pressure loss over all pipe segments is:

where:

ν is the fluid kinematic viscosity.

λ is the value of the Laminar friction constant for Darcy friction factor parameter, which you can define when the Cross-sectional geometry parameter is

Customand is otherwise equal to 64.D is the pipe hydraulic diameter.

Ladd is the value of the Aggregate equivalent length of local resistances parameter.

A is the mass flow rate at port A.

B is the mass flow rate at port B.

When the Reynolds number is greater than the Turbulent flow lower Reynolds number limit, the pressure loss in the pipe is:

where:

f is the Darcy friction factor. This is approximated by the empirical Haaland equation and is based on the Surface roughness specification, ε, and pipe hydraulic diameter:

Pipe roughness for brass, lead, copper, plastic, steel, wrought iron, and galvanized steel or iron are provided as ASHRAE standard values. You can also supply your own Internal surface absolute roughness with the

Customsetting.ρI is the internal fluid density.

When the Local resistances specification parameter is set

to Local loss coefficient and the flow in the pipe is

lower than the Laminar flow upper Reynolds number limit,

the pressure loss over all pipe segments is:

When the Reynolds number is greater than the Turbulent flow lower Reynolds number limit, the pressure loss in the pipe is:

where Closs,total is the loss coefficient, which can be defined in the Total local loss coefficient parameter as either a single coefficient or the sum of all loss coefficients along the pipe.

The Nominal Pressure Drop vs. Nominal Mass Flow Rate parameterization characterizes losses with a loss coefficient for rigid or flexible walls. When the fluid is incompressible, the pressure loss over the entire pipe due to wall friction is:

where Kp is:

where:

ΔpN is the Nominal pressure drop, which can be defined either as a scalar or a vector.

is the Nominal mass flow rate, which can be defined either as a scalar or a vector.

When the you supply the Nominal pressure drop and Nominal mass flow rate parameters as vectors, the scalar value Kp is determined from a least-squares fit of the vector elements.

Pressure losses due to viscous friction can also be determined from user-provided tabulated data of the Darcy friction factor vector and the Reynolds number vector for turbulent Darcy friction factor parameters. Linear interpolation is employed between data points.

Momentum Balance

The pressure differential over the pipe is due to the pressure at the pipe ports, friction at the pipe walls, and hydrostatic changes due to any change in elevation:

where:

pA is the pressure at a port A.

pB is the pressure at a port B.

Δpf is the pressure differential due to viscous friction, Δpf,A+Δpf,B.

g is the value of the Gravitational acceleration parameter or the signal at port G.

Δz the elevation differential between port A and port B, or zA - zB.

ρI is the internal fluid density, which is measured at each pipe segment. If fluid dynamic compressibility is not modeled, this is:

When fluid inertia is not modeled, the momentum balance between port A and internal node I is:

When fluid inertia is not modeled, the momentum balance between port B and internal node I is:

When fluid inertia is modeled, the momentum balance between port A and internal node I is:

where:

A is the fluid inertia at port A.

L is the value of the Pipe length parameter.

S is the value of the Nominal cross-sectional area parameter.

When fluid inertia is modeled, the momentum balance between port B and internal node I is:

where

B is the fluid inertia at port B.

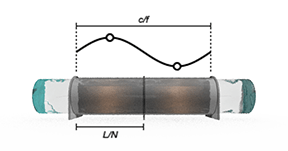

Pipe Discretization

You can divide the pipe into multiple segments. If a pipe has more than one segment, the mass flow, energy flow, and momentum balance equations are calculated for each segment. Having multiple pipe segments can allow you to track changes to variables such as fluid density when fluid dynamic compressibility is modeled.

If you would like to capture specific phenomena in your application, such as water hammer, choose a number of segments that provides sufficient resolution of the transient. The following formula, from the Nyquist sampling theorem, provides a rule of thumb for pipe discretization into a minimum of N segments:

where:

L is the Pipe length.

f is the transient frequency.

c is the speed of sound.

For some applications, you may need to connect Pipe (TL) blocks in series. For example, you may require multiple pipe segments to define a thermal boundary condition along the length of a pipe. In this case, model the pipe segments by using a Pipe (TL) block for each segment and use the thermal ports to set the thermal boundary condition.

Mass Balance

For a rigid pipe with an incompressible fluid, the pipe mass conversation equation is:

where:

A is the mass flow rate at port A.

B is the mass flow rate at port B.

For a flexible pipe with an incompressible fluid, the pipe mass conservation equation is:

where:

ρI is the thermal liquid density at internal node I. Each pipe segment has an internal node.

is the rate of deformation of the pipe volume.

For a flexible pipe with a compressible fluid, the mass within the pipe can change with pressure and temperature. The bulk modulus and thermal expansion coefficient of the thermal liquid account for this dependence and the pipe mass conservation equation is:

where:

pI is the thermal liquid pressure at the internal node I.

I is the rate of change of the thermal liquid temperature at the internal node I.

βI is the thermal liquid bulk modulus.

αI is the liquid thermal expansion coefficient.

Energy Balance

The energy accumulation rate in the pipe at internal node I is defined as:

where:

ϕA is the energy flow rate at port A.

ϕB is the energy flow rate at port B.

QH is the heat transfer through the pipe wall.

If the fluid is incompressible, the expression for energy accumulation rate is

where:

cpI is the fluid specific heat at the internal node of the block.

V is the pipe volume.

If the fluid is compressible, the expression for energy accumulation rate is

where:

and hI is the specific enthalpy at the internal node of the block.

If the fluid is compressible and the pipe walls are flexible, the expression for energy accumulation rate is

Ports

Input

Conserving

Parameters

References

[1] Budynas R. G. Nisbett J. K. & Shigley J. E. (2004). Shigley's mechanical engineering design (7th ed.). McGraw-Hill.

[2] Cengel, Y.A. Heat and Mass Transfer: A Practical Approach (3rd edition). New York, McGraw-Hill, 2007

[3] Ju Frederick D., Butler Thomas A., Review of Proposed Failure Criteria for Ductile Materials (1984) Los Alamos National Laboratory.

[4] Hencky H (1924) Zur Theorie plastischer Deformationen und der hierdurch im Material hervorgerufenen Nachspannungen. Z Angew Math Mech 4:323–335

[5] Jahed H, “A Variable Material Property Approach for Elastic-Plastic Analysis of Proportional and Non-proportional Loading, (1997) University of Waterloo