Tank (TL)

Thermal liquid container with variable fluid volume

Libraries:

Simscape /

Fluids /

Thermal Liquid /

Tanks & Accumulators

Description

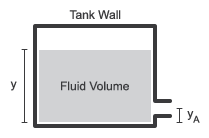

The Tank (TL) block models a thermal liquid container with a variable fluid volume. The absolute pressure of the tank fluid volume is assumed constant and equal to the value specified in the block dialog box. In the special case that the tank pressurization is equal to atmospheric pressure, the block represents a vented tank.

The tank can exchange energy with its surroundings, allowing its internal temperature and pressure to evolve over time. Heat transfer occurs via convection, as liquid enters or exits the chamber, and conduction, as thermal energy flows through the tank walls and the liquid itself at the tank inlets.

Tank Schematic

The tank can have up to six input ports, A through F. The pressure at the tank inlets is the sum of the constant tank pressurization specified in the block dialog box and the hydrostatic pressure due to the inlet height.

The tank model accounts for heat transfer through the tank wall, associated with thermal conserving port H. The temperature defined at this port is the temperature of the tank fluid volume.

Tank Volume

The tank fluid volume is computed from the total fluid mass at each time step:

where:

V is the tank fluid volume.

M is the tank fluid mass.

ρ is the tank fluid density.

Mass Balance

The mass conservation equation in the tank fluid volume is

where:

is the change in fluid mass.

denotes the mass flow rates into the tank fluid volume through port η.

Momentum Balance

The momentum conservation equation in the tank fluid volume for port η with is

where:

pη is the fluid pressure at inlet η.

pRef is the constant tank pressurization.

pdyn is the dynamic pressure:

When the flow direction is into tank, the incoming jet dissipates into the large fluid volume, loses momentum, and causes pdyn to be

0. When the fluid flows out of the tank, the fluid in the volume accelerates into the port and causes pdyn to be greater than0.ρη is the liquid density at port η.

SIA is the tank inlet area.

g is the gravitational constant.

y is the tank level, or height, relative to the tank bottom.

yη is the tank inlet elevation relative to the tank bottom.

Energy Balance

The energy conservation equation in the tank fluid volume is

where:

Cp is the fluid thermal capacity.

α is the fluid isobaric bulk modulus.

T is the fluid temperature.

Φη denotes the energy flow rates into the tank through port η.

h is the fluid enthalpy.

Q is the thermal energy flow rate into the tank through port H.

Examples

Assumptions and Limitations

The tank pressure is constant and uniform throughout the tank volume. The tank elevation head affects only the inlet pressure calculations.

Fluid momentum is lost at the tank inlet due to the sudden expansion into the tank volume.

When you set the Pressurization specification parameter to

Variable pressure, the block assumes that variation in pressure occurs slowly and there is no pressure derivative in the mass and energy balance equations.