Torque Converter

Viscous fluid coupling between rotating driveline shafts

Libraries:

Simscape /

Driveline /

Couplings & Drives

Description

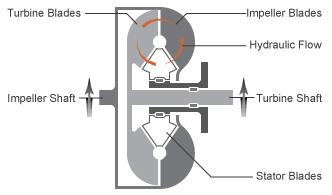

The Torque Converter block models a torque converter. The Torque Converter block has two mechanical rotational conserving ports that are associated with the impeller and turbine, respectively. The block transfers torque and angular velocity between the impeller port I and turbine port T by acting as a lookup table. The block can simulate drive (power flows from I port to T port) and coast (power flows from T port to I port) modes.

Examples

Limitations

When Coast mode modeling is set to

Continuous:

The impeller shaft must always rotate in a positive direction. Simulation is not valid for < 0.

If you drive the Torque Converter block by using a torque source, such as the Generic Engine block, you must include an inertia in the source to represent the engine, shaft inertia, or other source components. To ensure that the impeller starts by rotating in a positive direction, set the initial speed for this inertia to a positive value.

Ports

Conserving

I — Impeller

mechanical rotational

Mechanical rotational conserving port associated with the impeller.

T — Turbine

mechanical rotational

Mechanical rotational conserving port associated with turbine.

Parameters

Torque Characteristics

Coast mode modeling — Modeling type of torque converter

Two-mode (default) | Continuous

Modeling type of the torque converter specified as either

Two-mode or Continuous. The

Continuous modeling type supports both drive and coast

modes but has reduced accuracy and robustness when modeling near the transition

between coasting and driving modes. Therefore, if the simulation involves a coast

mode, use the Two-mode modeling type due to its better

robustness and accuracy when modeling the coast mode.

Drive mode speed ratio vector — Turbine speed to impeller speed ratios

[0, .5, .6, .7, .8, .87, .92, .94, .96, .97, 1] (default) | vector

Speed ratios, , of the drive mode. The vector elements must be in ascending order starting at 0 and ending at 1.

Dependencies

To enable this parameter, set Coast mode modeling to

Two-mode.

Drive mode torque ratio vector — Turbine torque to impeller torque ratios

[2.232, 1.5462, 1.4058, 1.2746, 1.1528, 1.0732, 1.0192, 1, 1, 1,

1] (default) | vector

Torque ratios, , of the drive mode. Each element of the vector must be greater than or equal to 1, and the last element must be 1.

Dependencies

To enable this parameter, set Coast mode modeling to

Two-mode.

Drive mode capacity factor vector — Capacity factors of drive mode

1e-4 * [.72558, .66322, .63463, .59042, .51331, .4144, .29287,

.22444, .12186, .04386, 0] m*N/rpm^2 (default) | vector

Capacity factors,, of the drive mode. Each element of the vector must be nonnegative, and the last element must be 0.

Dependencies

To enable this parameter, set Coast mode modeling to

Two-mode.

Coast mode speed ratio vector — Impeller speed to turbine speed ratios

[0, .5, .6, .7, .8, .87, .92, .94, .96, .97, 1] (default) | vector

Speed ratios, , of the coast mode. The vector elements must be in ascending order starting at 0 and ending at 1.

Dependencies

To enable this parameter, set Coast mode modeling to

Two-mode.

Coast mode capacity factor vector — Capacity factors of coast mode

1e-4 * [.5079, .4643, .4442, .4133, .3593, .2901, .205, .1571,

.0853, .0307, 0] m*N/rpm^2 (default) | vector

Capacity factors, , of the coast mode. Each element of the vector must be nonnegative, and the last element must be 0.

Dependencies

To enable this parameter, set Coast mode modeling to

Two-mode.

Interpolation method — Interpolation method of lookup function

Linear (default) | Smooth

Interpolation method of the lookup function, specified as either

Linear or Smooth. The method

interpolates torque ratio and capacity factor functions between the discrete relative

velocity values within the definition range. For more information about

Linear and Smooth, see tablelookup.

Extrapolation method — Extrapolation method of lookup function

Linear (default) | Nearest | Error

Extrapolation method of the lookup function, specified as

Linear, Smooth, or

Error. The method extrapolates torque ratio and capacity

factor functions. For more information about Linear,

Smooth, and Error, see tablelookup.

Initial mode — Initial mode of simulation

Drive mode (default) | Coast mode

Initial mode of the simulation, specified as either Drive

mode or Coast mode.

Mode transition threshold — Threshold of mode transition

1 rpm (default) | positive scalar

Mode transition threshold of the simulation. Setting a threshold for the mode transition can increase the simulation robustness by avoiding the high frequency mode switching.

Dependencies

To enable this parameter, set Coast mode modeling to

Two-mode.

Speed ratio vector — Turbine speed to impeller speed ratios

[0, .5, .6, .7, .8, .87, .92, .94, .96, .97] (default) | vector

Speed ratios, , of the torque converter. Each element of the vector must be in ascending order and in the range [0,1].

Dependencies

To enable this parameter, set Coast mode modeling to

Continuous.

Torque ratio vector — Turbine torque to impeller torque ratios

[2.232, 1.5462, 1.4058, 1.2746, 1.1528, 1.0732, 1.0192, .9983,

.9983, .9983, .9983] (default) | vector

Torque ratios, , of the torque converter. Each element of the vector must be positive.

Dependencies

To enable this parameter, set Coast mode modeling to

Continuous.

Capacity factor parameterization — Definition of capacity factor

Ratio of speed to square root of impeller

torque (default) | Ratio of impeller torque to square of speed

Definition of the capacity factor of the converter, defined as either

Ratio of speed to square root of impeller torque or

Ratio of impeller torque to square of speed. The setting

of this parameter affects the Capacity factor vector.

For

Ratio of speed to square root of impeller torqueparameter:For

Ratio of impeller torque to square of speedparameter:

Dependencies

To enable this parameter, set Coast mode modeling to

Continuous.

Capacity factor reference speed — Choice of speed for capacity factor definition

Always impeller speed (default) | Turbine speed for speed ratios greater than

one

Choice of speed for the capacity factor definition, specified as either

Always impeller speed or Turbine speed for

speed ratios greater than one.

Always impeller speed: Use impeller speed for all values of .Turbine speed for speed ratios greater than one: Use impeller speed for all values of < 1, and use turbine speed when > 1.

Dependencies

To enable this parameter, set Coast mode modeling to

Continuous.

Capacity factor vector — Capacity factors

[12.2938, 12.8588, 13.1452, 13.6285, 14.6163, 16.2675, 19.3503,

22.1046, 29.9986, 50] (rad/s)/(N*m)^0.5 (default) | vector

Capacity factors of the converter. You can define the capacity factor as:

Capacity factor

|

| Set Capacity factor parameterization parameter to

Ratio of speed to square root of impeller

torque. |

|

| Set Capacity factor parameterization parameter to

Ratio of impeller torque to the square of the

speed. The default value is 1e-3 * [6.616, 6.048, 5.787,

5.384, 4.681, 3.779, 2.671, 2.047, 1.111, .4]

N*m/(rad/s)^2. |

Note

If you do not specify capacity factor data for a speed ratio of 1, the block uses a capacity factor value of 10*KMax, where KMax is the maximum value in the specified capacity factor vector. The corresponding torque ratio is assumed to be 0. For all other speed ratio values not explicitly specified in the lookup table data, the block uses the interpolation or extrapolation method selected in the block property inspector.

Dependencies

To enable this parameter, set Coast mode modeling to

Continuous.

Dynamics

To enable the Dynamics, set the Coast mode

modeling parameter to Continuous.

Model transmission lag — Transmission lag setting

No lag – Suitable for HIL

simulation (default) | Specify time constant and initial value

Transmission lag setting, specified as either No lag – Suitable for

HIL simulation or Specify time constant and initial

value.

No lag – Suitable for HIL simulation: Torque transfer is instantaneous.When there is no time lag, the input impeller torque, , and output turbine torque, , are:

Specify time constant and initial value: Torque is transferred with a time lag. If you select this option, you can specify the Torque transmission time constant and Initial turbine-to-impeller torque ratio parameters.Note

For optimal simulation performance, select

No lag - Suitable for HIL simulation.

Torque transmission time constant — Time constant of torque transmission

.02 s (default) | positive scalar

Torque transmission time. The time lag increases model fidelity but reduces simulation performance. See Adjust Model Fidelity for more information.

Dependencies

To enable this parameter, set Model transmission lag to

Specify time constant and initial value.

Initial turbine-to-impeller torque ratio — Initial torque ratio of turbine to impeller

0 (default) | positive scalar

Initial torque ratio of the turbine to the impeller.

You can optionally include the effect of torque transmission time lag that is caused by internal fluid flow and compressibility. Instead of and being instantaneously constrained to one another, a first-order time lag introduces a delayed response in the impeller torque:

The preceding instantaneous function of the capacity factor K determines the steady-state value of τI.

Dependencies

To enable this parameter, set Model transmission lag to

Specify time constant and initial value.

References

[1] Society of Automotive Engineers, Hydrodynamic Drive Test Code (Surface Vehicle Recommended Practice), SAE J643, Dec 2018.

Extended Capabilities

C/C++ Code Generation

Generate C and C++ code using Simulink® Coder™.

Version History

Introduced in R2011a

See Also

Simscape Blocks

Topics

MATLAB Command

You clicked a link that corresponds to this MATLAB command:

Run the command by entering it in the MATLAB Command Window. Web browsers do not support MATLAB commands.

Select a Web Site

Choose a web site to get translated content where available and see local events and offers. Based on your location, we recommend that you select: .

You can also select a web site from the following list:

How to Get Best Site Performance

Select the China site (in Chinese or English) for best site performance. Other MathWorks country sites are not optimized for visits from your location.

Americas

- América Latina (Español)

- Canada (English)

- United States (English)

Europe

- Belgium (English)

- Denmark (English)

- Deutschland (Deutsch)

- España (Español)

- Finland (English)

- France (Français)

- Ireland (English)

- Italia (Italiano)

- Luxembourg (English)

- Netherlands (English)

- Norway (English)

- Österreich (Deutsch)

- Portugal (English)

- Sweden (English)

- Switzerland

- United Kingdom (English)