MATLAB and Simulink Videos

Learn about MATLAB® and Simulink®, watch demonstrations about how to get started, and explore what’s new.

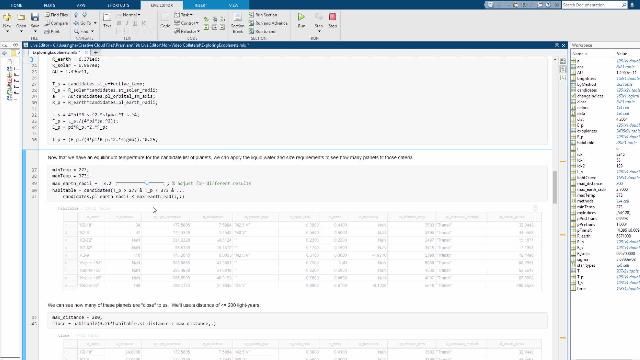

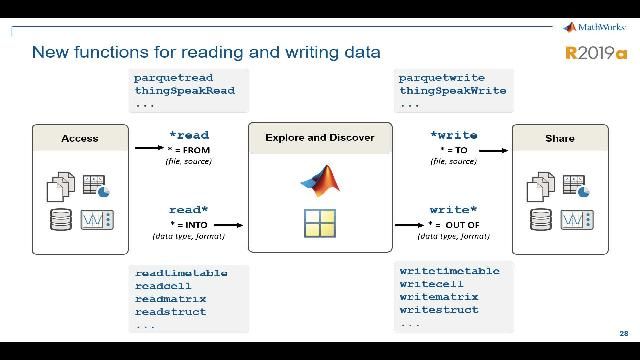

- MATLAB

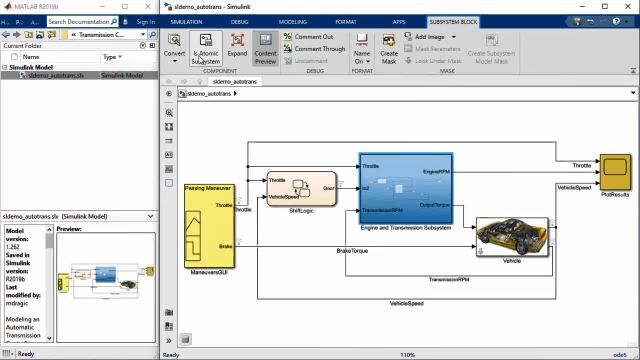

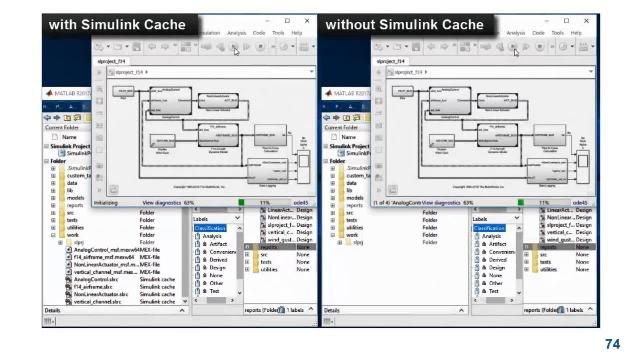

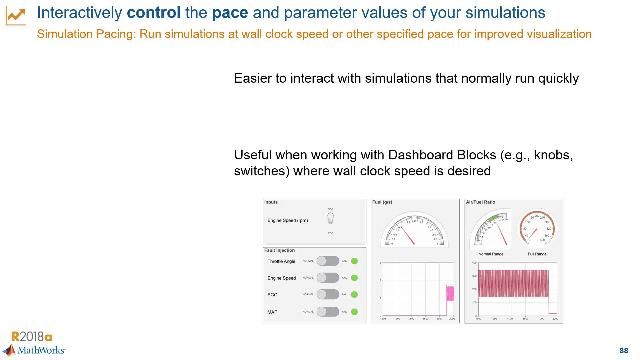

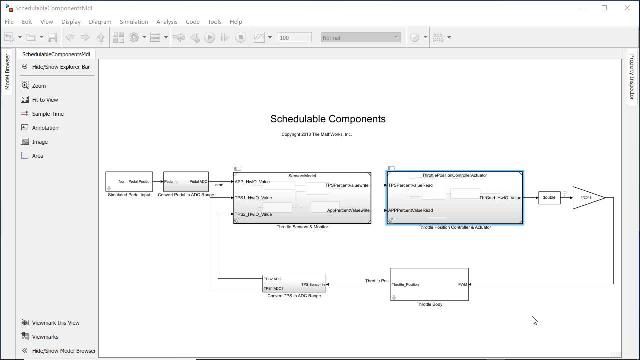

- Simulink

- 5G Toolbox

- Aerospace Blockset

- Aerospace Toolbox

- Antenna Toolbox

- Audio Toolbox

- Automated Driving Toolbox

- AUTOSAR Blockset

- Bioinformatics Toolbox

- Bluetooth Toolbox

- C2000 Microcontroller Blockset

- Communications Toolbox

- Computer Vision Toolbox

- Control System Toolbox

- Curve Fitting Toolbox

- Data Acquisition Toolbox

- Database Toolbox

- Datafeed Toolbox

- DDS Blockset

- Deep Learning HDL Toolbox

- Deep Learning Toolbox

- DO Qualification Kit

- DSP HDL Toolbox

- DSP System Toolbox

- Econometrics Toolbox

- Embedded Coder

- Filter Design HDL Coder

- Financial Instruments Toolbox

- Financial Toolbox

- Fixed-Point Designer

- Fuzzy Logic Toolbox

- Global Optimization Toolbox

- GPU Coder

- HDL Coder

- HDL Verifier

- IEC Certification Kit

- Image Acquisition Toolbox

- Image Processing Toolbox

- Industrial Communication Toolbox

- Instrument Control Toolbox

- Lidar Toolbox

- LTE Toolbox

- Mapping Toolbox

- MATLAB Coder

- MATLAB Compiler

- MATLAB Compiler SDK

- MATLAB Online Server

- MATLAB Parallel Server

- MATLAB Production Server

- MATLAB Report Generator

- MATLAB Test

- MATLAB Web App Server

- Medical Imaging Toolbox

- Mixed-Signal Blockset

- Model Predictive Control Toolbox

- Model-Based Calibration Toolbox

- Motor Control Blockset

- Navigation Toolbox

- Optimization Toolbox

- Parallel Computing Toolbox

- Partial Differential Equation Toolbox

- Phased Array System Toolbox

- Polyspace Access

- Polyspace Bug Finder

- Polyspace Bug Finder Server

- Polyspace Client for Ada

- Polyspace Code Prover

- Polyspace Code Prover Server

- Polyspace Server for Ada

- Polyspace Test

- Powertrain Blockset

- Predictive Maintenance Toolbox

- Radar Toolbox

- Reinforcement Learning Toolbox

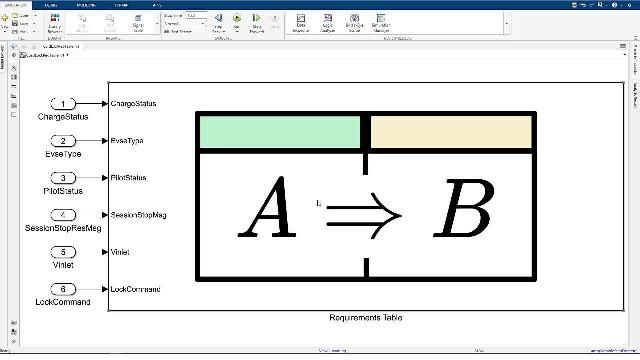

- Requirements Toolbox

- RF Blockset

- RF PCB Toolbox

- RF Toolbox

- Risk Management Toolbox

- RoadRunner

- RoadRunner Asset Library

- RoadRunner Scenario

- RoadRunner Scene Builder

- Robotics System Toolbox

- Robust Control Toolbox

- ROS Toolbox

- Satellite Communications Toolbox

- Sensor Fusion and Tracking Toolbox

- SerDes Toolbox

- Signal Integrity Toolbox

- Signal Processing Toolbox

- SimBiology

- SimEvents

- Simscape

- Simscape Battery

- Simscape Driveline

- Simscape Electrical

- Simscape Fluids

- Simscape Multibody

- Simulink 3D Animation

- Simulink Check

- Simulink Code Inspector

- Simulink Coder

- Simulink Compiler

- Simulink Control Design

- Simulink Coverage

- Simulink Design Optimization

- Simulink Design Verifier

- Simulink Desktop Real-Time

- Simulink Fault Analyzer

- Simulink PLC Coder

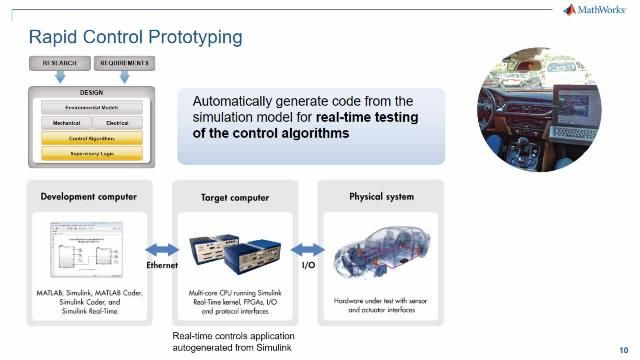

- Simulink Real-Time

- Simulink Report Generator

- Simulink Test

- SoC Blockset

- Spreadsheet Link

- Stateflow

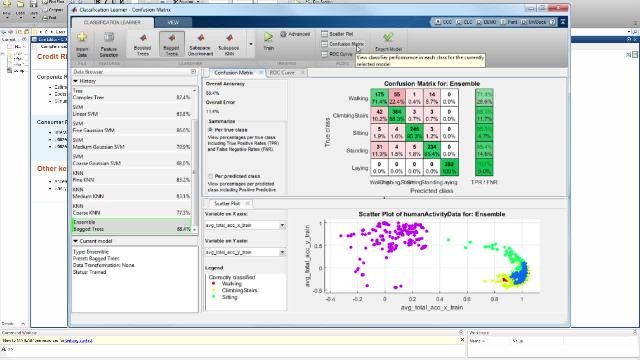

- Statistics and Machine Learning Toolbox

- Symbolic Math Toolbox

- System Composer

- System Identification Toolbox

- Text Analytics Toolbox

- ThingSpeak

- UAV Toolbox

- Vehicle Dynamics Blockset

- Vehicle Network Toolbox

- Vision HDL Toolbox

- Wavelet Toolbox

- Wireless HDL Toolbox

- Wireless Testbench

- WLAN Toolbox