Wind Turbine Induction Generator (Phasor Type)

Implement phasor model of squirrel-cage induction generator driven by variable pitch wind turbine

Libraries:

Simscape /

Electrical /

Specialized Power Systems /

Electrical Machines

Description

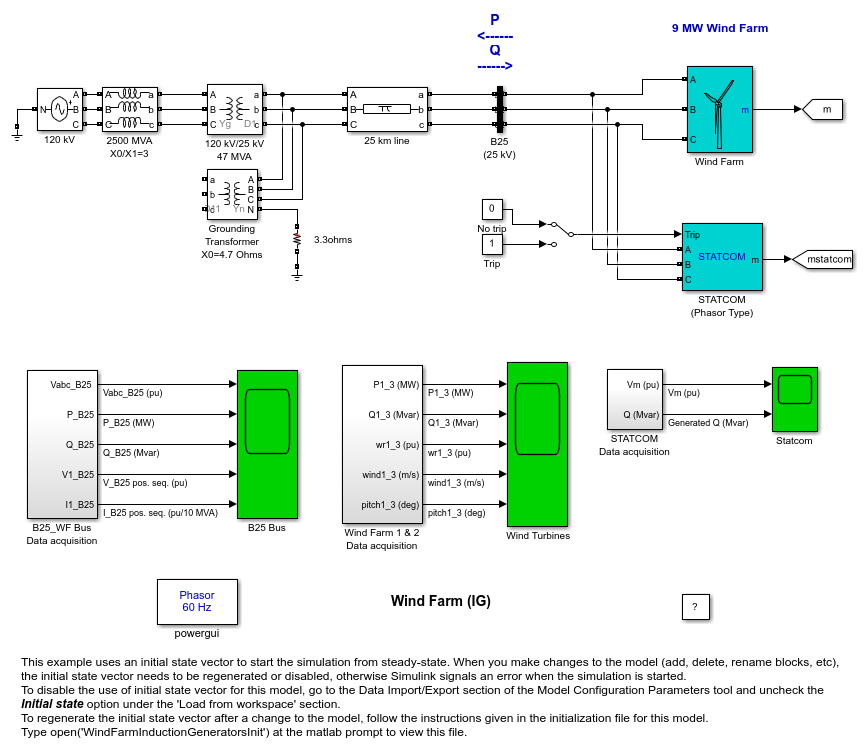

The wind turbine and the induction generator (WTIG) are shown below. The stator winding is connected directly to the grid and the rotor is driven by the wind turbine. The power captured by the wind turbine is converted into electrical power by the induction generator and is transmitted to the grid by the stator winding. The pitch angle is controlled in order to limit the generator output power to its nominal value for high wind speeds. In order to generate power the induction generator speed must be slightly above the synchronous speed. But the speed variation is typically so small that the WTIG is considered to be a fixed-speed wind generator. The reactive power absorbed by the induction generator is provided by the grid or by some devices like capacitor banks, SVC, STATCOM, or synchronous condenser.

Pitch Angle Control System

The wind turbine model uses the Wind Turbine block of the Renewables/Wind Generation library. See documentation of this block for details.

A Proportional-Integral (PI) controller is used to control the blade pitch angle in

order to limit the electric output power to the nominal mechanical power. The pitch angle is

kept constant at zero degrees when the measured electric output power is under its nominal

value. When it increases above its nominal value, the PI controller increases the pitch

angle to bring back the measured power to its nominal value. The control system is

illustrated in the figure below:

Examples

Ports

Input

Output

Conserving

Parameters

References

[1] Siegfried Heier, “Grid Integration of Wind Energy Conversion Systems,” John Wiley & Sons Ltd, 1998, ISBN 0-471-97143-X

Extended Capabilities

Version History

Introduced in R2006a