Single-Acting Actuator (TL)

Single-acting linear actuator in a thermal liquid network

Libraries:

Simscape /

Fluids /

Thermal Liquid /

Actuators

Description

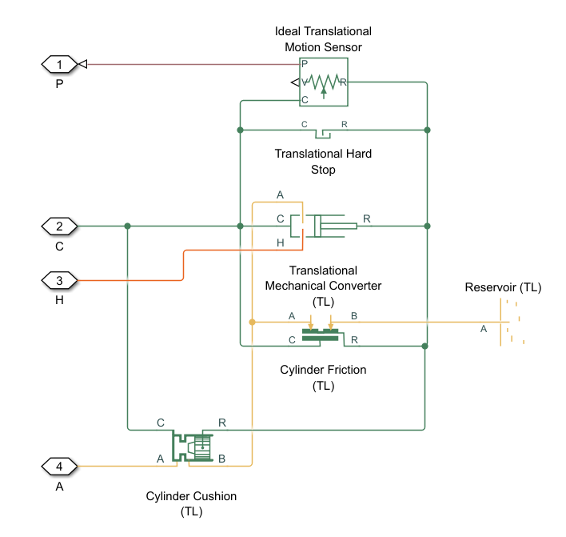

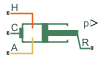

The Single-Acting Actuator (TL) block models a linear actuator with a piston controlled by a single thermal liquid chamber. The actuator generates force in the extension and retraction strokes, but the actuation force depends on the gauge pressure at a single chamber.

The figure shows the key components of an actuator. Port A represents the thermal liquid chamber inlet. Port R represents the translating actuator piston, and port C represents the actuator case. Port H represents the thermal interface between the thermal liquid chamber and the environment.

Displacement

The block measures the piston displacement as the position at port

R relative to port C. The Mechanical

orientation parameter identifies the direction of piston displacement. The

piston displacement is neutral, or 0, when the chamber volume is equal to

the value of the Dead volume parameter. When the Piston

displacement parameter is Provide input signal from Multibody

joint, you input the piston displacement using port p.

You can ensure that the derivative of the position signal is equal to the piston velocity by

using a Translational Multibody Interface block to provide the

piston displacement.

The direction of the piston motion depends on the Mechanical orientation parameter. If the mechanical orientation is positive, then the piston translation is positive in relation to the actuator case when the gauge pressure at port A is positive. The direction of motion reverses when the mechanical orientation is negative.

Hard Stop

A set of hard stops limit the piston range of motion. The block uses an implementation of the Translational Hard Stop block, which treats hard stops like spring-damper systems. The spring stiffness coefficient controls the restorative component of the hard-stop contact force and the damping coefficient the dissipative component.

The hard stops are located at the distal ends of the piston stroke. If the mechanical orientation is positive, then the lower hard stop is at x = 0, and the upper hard stop is at x = +stroke. If the mechanical orientation is negative, then the lower hard stop is at x = -stroke, and the upper hard stop is at x = 0.

Cushion

The block can model cushioning toward the extremes of the piston stroke. Select Cylinder end cushioning to slow the piston motion as it approaches the maximum extension, defined by the Piston stroke parameter. For more information on the functionality of a cylinder cushion, see the Cylinder Cushion (TL) block.

Friction

The block can model friction against piston motion. When you select Cylinder friction, the resulting friction is a combination of the Stribeck, Coulomb, and viscous effects. The block measures the pressure difference between the chamber pressure and the environment pressure. For more information on the friction model and its limitations, see the Cylinder Friction (TL) block.

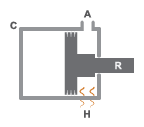

Block Composite

This block is a composite component based on these Simscape™ Foundation blocks:

If you select Cylinder friction or Cylinder end cushioning, the block composite also includes the Cylinder Friction (TL) block or Cylinder Cushion (TL) block.