TWT GmbH Develops New Workflow for Tuning Automotive Suspension Designs Using Deep Learning and Multibody Simulation

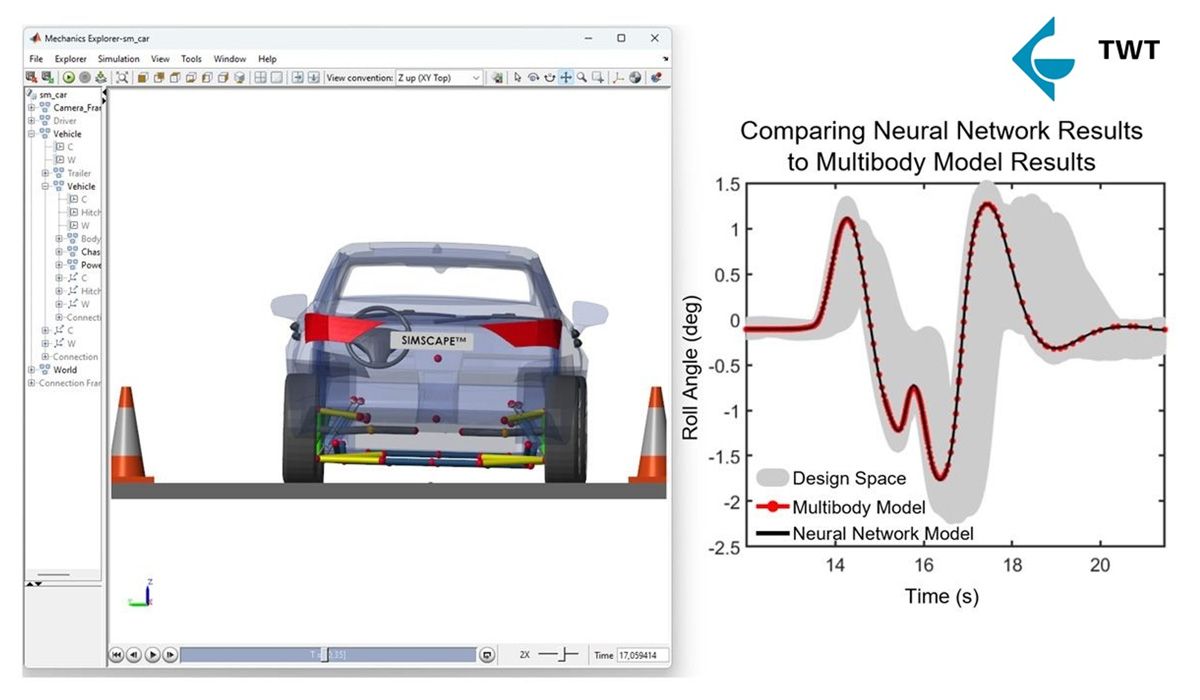

“As expected, performance was satisfactory, proving that all three networks could generalize well on new data. While the Keras neural network managed to fit the first peak almost perfectly, it was not as accurate with the remaining plot. The hybrid neural network was an improvement and generally fit the real curve. Finally, as expected, the MATLAB neural network had the best performance, and its prediction was extremely accurate.”

Key Outcomes

- New workflow with MATLAB and Simulink improved suspension design, helping reduce roll angle by up to 50%

- Using Global Optimization Toolbox reduced optimization time for suspension simulations from 16 days to 5 minutes

- Single-environment workflow established for multibody simulation and deep learning

Research engineers at TWT GmbH Science & Innovation use simulation to optimize automotive suspension designs. The optimization process has traditionally required running thousands of simulations to explore the ranges of a large set of parameters within the multibody model as it performs a specific maneuver. The simulations are computationally intensive, including tightly coupled, highly nonlinear effects, so the optimized result can take days to find.

In the new workflow, a high-fidelity Simscape™ model is used to generate training data for a deep learning network, which is then used to evaluate changes in suspension components and run optimizations. In validating this approach, a TWT engineer began by customizing an example Simscape Vehicle Template downloaded from MathWorks. After using the model to simulate a standard ISO® double lane change maneuver in Simulink®, the engineer performed sensitivity analyses using MATLAB® to reduce the number of training input parameters and created a design of experiments with a Latin hypercube sample.

Using Deep Learning Toolbox™, he created a network and trained it using the Levenberg-Marquardt (LM) algorithm. He also performed this step in Python® but found that the MATLAB implementation of the LM algorithm yielded better results for curve-fitting problems. Finally, he used Global Optimization Toolbox to run optimizations using the trained deep learning network to make inferences and significantly reduce the time needed to identify a set of parameters that minimized the vehicle’s roll angle during the maneuver.